Digital Denture Resource Center

Harness the accuracy & efficiency of digital impressions with Maverick’s first-in-class digital design & 3D printing techniques to get a truly superior workflow & result.

Digital Dentures with Maverick

OUR GOAL:

Maverick has invested into best-in-class technologies, advanced materials & improved workflows to create a superior clinical experience with 3D Printed Dentures. This means stronger materials, faster turnarounds & more precise fits by harnessing the power of digital for your denture cases.

PRINTED DENTURE MATERIALS:

Printed Lucitone Base: Maverick utilizes Dentsply’s Lucitone Print resin for its Digital Denture bases. Offering proven biocompatibility, esthetics & improved characteristics: The high-impact resin exceeds ISO standards for impact resistance, delivering outstanding durability and strength. Featuring a smart polymer technology, the body-activated material (BAM!) nearly doubles its ability to resist breakage when worn. Future repairs & relines are easy to perform with standard acrylic methods.

Printed Denture Teeth: As a premium-level material, Maverick prints Digital Denture teeth with Dentsply’s Digital IPN tooth resin. This resin offers the same superior durability of traditional IPN and outperforms competitive 3D denture tooth materials available today in terms of wear resistance.

PRICING & TURNAROUND:

Ahead of the official product launch, prices will be heavily discounted.

*Turnaround time does not include delivery days.

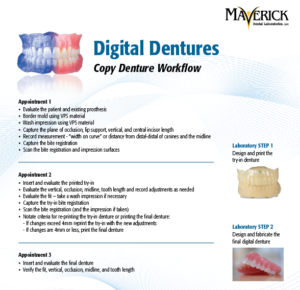

HOW IT WORKS, 2 DIFFERENT WORKFLOWS:

New Denture (see full video below for further instruction):

Duplicate an Existing Denture (see full video below for further instruction):

DENTURE TRY-IN CHECKLIST (send with your Try-ins):